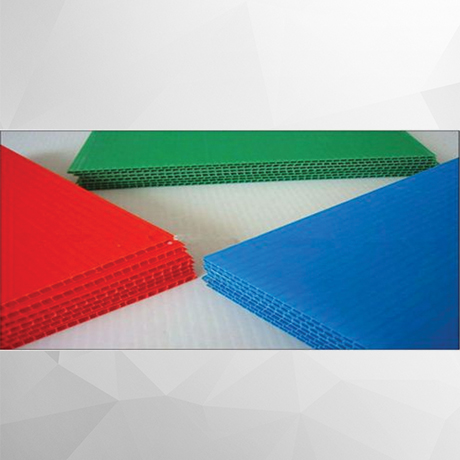

TILE PROTECTION SHEET

Products Description

Tile Protection Sheets consist of two , three, five & seven layer, bound together by a chemically prepared binding agent through a heat process. The first layer is called a surface coat, which has a rough texture to impart an anti skidding property to it. It has the tendency to reflect ultraviolet light. The second layer is a compact, polymer sack material. It is highly notch impact resistant. This layer has high tensile strength, resisting wear and tear. Further, an extra bonding base coat layer ensures extra strength, rigidity and shore hardness. These properties make it durable and attrition resistant. The next layer is a stretched, polymer based sheet. It has great elasticity and hence, higher recovering capacity after compression as compared to bubble sheets. The final is a base coat which is a high strength, protective material with a rough finish.

Parameters:

GRAMS / Square MeterMIN. 200, MAX. 300

THICKNESS (mm) 2 (tolerance + 5% )

WIDTH (meter)4 foot ( tolerance + 5% )

LENGTH (meter)6 foot ( tolerance + 2% ) Also available as per customer's requirements

FIELD OF APPLICATIONS To protect any type of flooring. [ e.g. vitrified, Marble, Granite, Wooden, Ceramic etc. ]

It can be used as upholstery parts in auto mobile industry.

Note: Specifications are as at the time of manufacturing, as per the standard conditions and subject to change without prior notice.

Floor sheet Installation

The size of the Floor sheet should be ordered according to the carpet area

The tiles along the carpet area should be cleared of any dust, grease or moisture

Dual sided adhesive tapes are then attached at regular spacing, along the sheet

The sheets are then spread over the carpet area and are sealed over the tiles with the tapes